A Comprehensive Guide to Wiring Three-Phase Motors with Diagrams and Best Practices

- Amindus Consulting and Solutions

- Nov 4, 2025

- 5 min read

Presented by Amindus Consulting and Solutions

Wiring three-phase motors may seem challenging at first, but it can be manageable with clear steps and the right information. This blog post provides a straightforward, step-by-step guide to wiring three-phase motors, featuring diagrams and visuals to enhance your understanding. You will learn about best practices, common mistakes to avoid, and essential safety precautions. Whether you're just starting out or are a seasoned electrician, this guide is designed to offer valuable insights into wiring three-phase motors effectively.

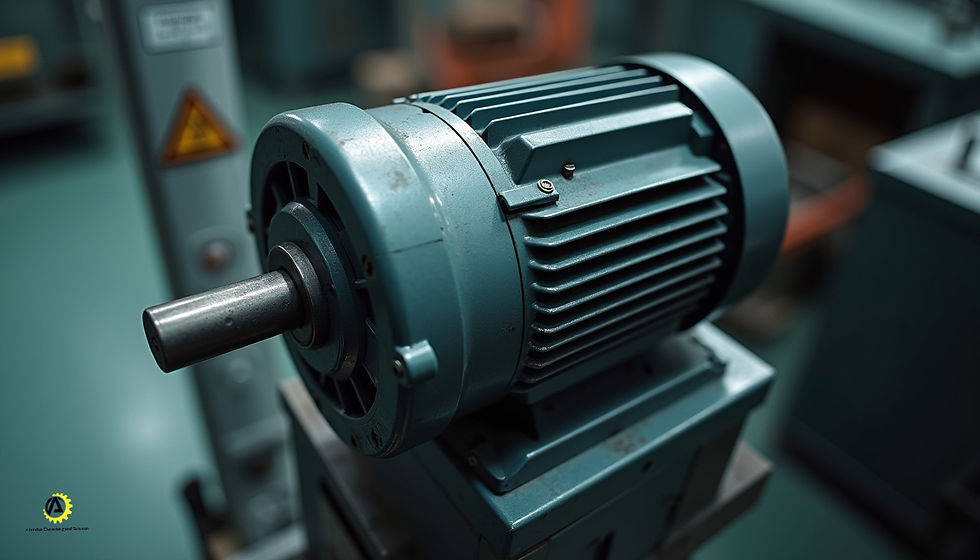

Understanding Three-Phase Motors

Three-phase motors are a staple in industrial settings due to their efficiency and reliability. Unlike single-phase motors, which operate with one alternating current, three-phase motors utilize three alternating currents. This setup results in smoother operation and increased power delivery, making them suitable for demanding applications such as:

Pumps: For moving water and other fluids in various contexts, three-phase motors can deliver consistent performance.

Compressors: In situations requiring air compression, these motors ensure better energy efficiency and reliability.

Conveyor Systems: With their ability to handle heavy loads, they are often used in production lines and material handling.

According to industry reports, three-phase motors can provide up to 30% more efficiency than single-phase motors, particularly in continuous duty operations.

Before starting the wiring process, familiarizing yourself with the key components is essential. The main components are:

Motor: The heart of the system that converts electrical energy into mechanical motion.

Power Supply: A three-phase power source typically connected to a distribution panel.

Contactor: An electrical device that acts as a switch to control the motor.

Overload Relay: A safety component designed to disconnect the motor in case of overheating, protecting it from damage.

Understanding these components simplifies the wiring process and increases the likelihood of success.

Step-by-Step Wiring Process

Step 1: Gather Necessary Tools and Materials

To begin the wiring process, you should have the following tools and materials ready:

Screwdrivers (flathead and Phillips)

Wire strippers

Multimeter for voltage checks

Electrical tape for securing connections

Three-phase motor

Contactor and overload relay

Correct wire gauge according to motor specifications

Having the right tools prepared will help make your wiring process more effective.

Step 2: Disconnect Power Supply

Safety should always come first when working with electrical systems. Before any wiring begins, ensure the power supply is completely disconnected. Use a multimeter to confirm there is no voltage present in the wires you will work on.

Step 3: Identify Motor Terminals

Most three-phase motors have three terminals marked U, V, and W (or L1, L2, and L3). These letters correspond to the three phases of the power supply. Always refer to the specific motor's wiring diagram for accurate terminal identification.

Step 4: Connect the Motor to the Contactor

Connect the Motor Terminals: Use the appropriate gauge wire to attach the motor terminals (U, V, W) to the corresponding terminals on the contactor. Ensure all connections are secured and wrapped with electrical tape for insulation.

Connect the Contactor to Power Supply: Connect the contactor to the three-phase power supply following the same protocol. Secure and insulate these connections as well.

Step 5: Install the Overload Relay

Install the overload relay between the contactor and the motor. This device checks the current flow and disconnects power if levels exceed safe limits. Follow the manufacturer's guidelines while wiring the overload relay.

Step 6: Ground the Motor

Grounding is critical for safety. Connect the motor's ground terminal to the grounding system in your electrical panel. This step significantly reduces the risk of electrical shock and protects the equipment.

Step 7: Double-Check Connections

Before re-applying power, revisit all connections to ensure they are secure and correctly wired. Look out for loose wires or exposed conductors that could create safety risks.

Step 8: Restore Power and Test the Motor

Once all connections are verified, restore power to the system. Check the voltage at the motor terminals with a multimeter. If everything checks out, turn on the motor. Pay attention to any unusual sounds and monitor its performance. A well-wired motor should run smoothly.

Best Practices for Installation

To enhance your installation's success, consider these best practices:

Follow Manufacturer Guidelines: Refer to the motor's wiring diagram and installation instructions to avoid mistakes and ensure safety compliance.

Use the Correct Wire Gauge: The wire gauge is crucial for preventing overheating. For example, if a motor runs at 20 amps, using a wire gauge of at least 12 or 10 AWG is advisable, depending on the distance and length of the wire run.

Label Wires Clearly: As you work, labeling wires can prevent confusion during installation and simplify future troubleshooting.

Maintain Proper Clearances: Ensure sufficient space around the motor for ventilation, which helps prevent overheating and extends the motor's service life.

Schedule Regular Maintenance: Regular inspections and maintenance can spot issues before they escalate, helping to prolong the motor's lifespan.

Common Mistakes to Avoid

Even experienced electricians can make errors when wiring. Here are some pitfalls to be aware of:

Incorrect Wiring: Always double-check connections against the wiring diagram, as mistakes can lead to significant damage or inefficiency.

Neglecting Grounding: Failing to ground properly can create shock hazards. Adhere to local codes for grounding procedures.

Using Inadequate Wire Gauge: If the wire gauge is too small for the motor's amperage, it may overheat. Consult the National Electrical Code (NEC) for correct wire gauge standards.

Ignoring Safety Protocols: Always adhere to safety protocols, including confirming power disconnection. Prioritize your safety and your colleagues' well-being.

Essential Safety Tips

Safety should be at the forefront of your wiring projects. Keep these essential tips in mind:

Wear Personal Protective Equipment (PPE): Protect yourself with gloves, goggles, and insulated footwear to reduce electrical risks.

Use Insulated Tools: Insulated tools minimize the chance of accidental shocks, making your work safer.

Work in a Dry Environment: Avoid moist conditions during wiring, as water and electricity create dangerous situations.

Keep the Work Area Organized: Maintain a tidy workspace to reduce distractions and accidents.

Know Emergency Procedures: Familiarize yourself with emergency protocols, such as quickly cutting power and knowing basic first aid.

Final Thoughts

Wiring three-phase motors is essential for electricians, offering many opportunities for efficient installations and safe operations. By following this step-by-step guide, applying best practices, and adhering to safety tips, you can ensure a secure wiring process.

Always put safety at the forefront and thoroughly check your work to avoid errors. With practice and attention to detail, you'll become proficient in wiring three-phase motors, enhancing your electrical skills.

By integrating these insights into your practices, you contribute to the safety and efficiency of electrical systems across various applications. Happy wiring!

Comments