The Rise of Dark Factories: Revolutionizing the Future of Manufacturing

- Amindus Consulting and Solutions

- Oct 9, 2025

- 5 min read

Presented by Amindus Consulting and Solutions

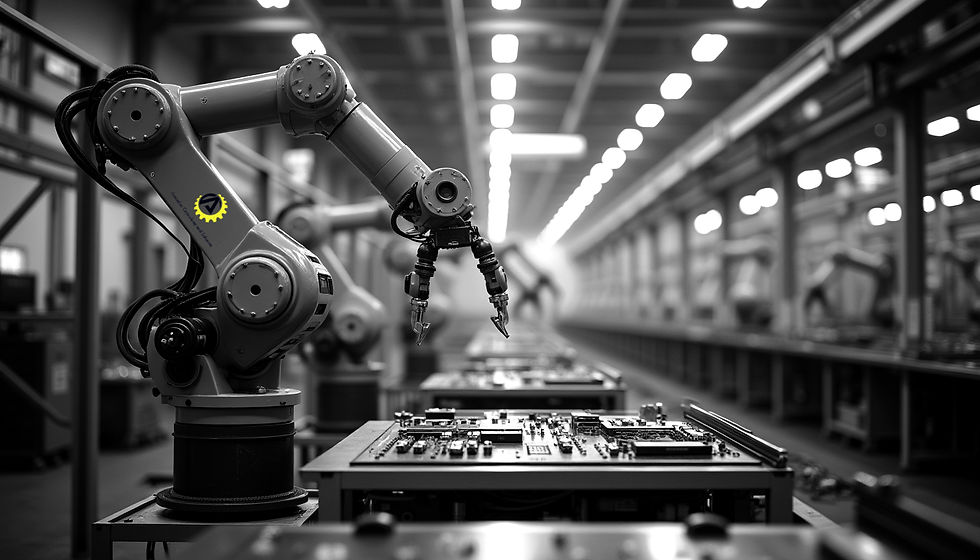

The concept of "dark factories" is emerging as a game-changing approach to production. These factories, designed for minimal human involvement and driven by cutting-edge automation, are set to transform how we make goods. As businesses confront the challenges of rising efficiency, lower costs, and growing consumer demands, dark factories offer a promising path forward. This post explores what dark factories are, their return on investment (ROI), why industry leaders are gravitating toward them, and how developing countries can draw valuable insights from these innovative models.

What Is a Dark Factory?

A dark factory is an automated manufacturing facility that operates with little to no human presence. These factories use technologies such as robotics, artificial intelligence (AI), and the Internet of Things (IoT) to streamline production. The term "dark" highlights the absence of workers on the factory floor, which allows for continuous operation without the constraints of traditional labor schedules.

The main goal of dark factories is to maximize efficiency and cut operational costs. By utilizing automation, they can run 24/7, leading to a significant boost in output and fewer human errors. For instance, a dark factory can increase production by up to 50%, allowing businesses to meet spikes in consumer demand more effectively. This shift toward automation is not merely a trend; it signals a fundamental change in manufacturing practices.

Are Dark Factories Worth the Investment? Insights on ROI for Manufacturers

Investing in dark factories involves careful consideration of the potential returns. Although the initial setup costs can be high, the long-term advantages often surpass these expenses. Here are a few important factors to think about when assessing the ROI of dark factories:

Increased Efficiency

Dark factories can operate continuously without breaks, leading to a dramatic rise in production capacity. For example, a factory that typically produces 1,000 units a day could ramp production to 1,500 units by implementing dark factory technology, effectively meeting rising consumer demands without a corresponding increase in labor costs.

Reduced Labor Costs

Automating tasks traditionally done by humans allows manufacturers to lower labor costs significantly. This helps in reducing not just wages but related expenses such as training, benefits, and safety measures. For instance, companies can save about 20-30% on labor costs by integrating automation.

Minimized Errors

Automation decreases the risk of human error, resulting in higher quality products and fewer defects. Research shows that manufacturers adopting dark factory models can reduce defect rates by as much as 90%, enhancing customer satisfaction and cutting costs associated with returns and rework.

Scalability

Dark factories provide a flexible production model that can easily adapt to changes in demand. When production needs rise or fall, manufacturers can adjust their automated systems swiftly, sidestepping the challenges of hiring or downsizing staff.

Data-Driven Insights

With IoT and AI working in tandem, dark factories enable real-time data collection and analysis. This data provides manufacturers with valuable insights that can optimize production processes and accelerate decision-making, ultimately leading to improved efficiency and reduced waste.

Despite high initial costs, the combination of enhanced efficiency, decreased costs, and improved product quality positions dark factories as a compelling choice for manufacturers seeking to maintain a competitive edge.

Why Forward-Thinking Leaders Are Betting on Dark Factories for 2030

As we look to the future, it's evident that progressive leaders in manufacturing are investing in dark factories for several reasons:

Technological Advancements

Rapid developments in robotics and AI are making dark factories increasingly viable and cost-effective. As these technologies improve, dark factories will become even more efficient. For example, the global robotic market is projected to grow by nearly 26% between now and 2030, indicating a broader trend that manufacturers should capitalize on.

Sustainability Goals

More manufacturers are focusing on sustainability. Dark factories help achieve these goals by optimizing energy use and minimizing waste. Research indicates that implementing automation can reduce energy consumption by 20-30%, significantly lowering a facility’s carbon footprint.

Global Competition

In a highly competitive global market, manufacturers must stay ahead. Dark factories facilitate lower costs and improved efficiency, enabling companies to compete effectively without sacrificing quality.

Changing Workforce Dynamics

As many industries grapple with labor shortages, dark factories provide a solution by employing automation where human resources are scarce. For example, a textile manufacturer in Spain used dark factory principles and saw their workforce decrease by 40% while increasing production capacity.

Consumer Expectations

Today's consumers demand faster delivery times and high-quality products. Dark factories can help manufacturers meet these expectations by streamlining production processes and ensuring consistent quality.

Together, these factors illustrate why dark factories are not just a passing trend but essential for manufacturers aiming to innovate and adapt in an ever-changing landscape.

What Developing Countries Can Learn from Dark Factory Models

Developing nations looking to strengthen their manufacturing capabilities can gain valuable insights from dark factory models. Here are key lessons:

Investment in Technology

Developing countries should prioritize adopting advanced manufacturing technologies. By integrating automation and AI, they can enhance production efficiency and become more competitive on a global scale.

Focus on Education and Training

While automation forms the backbone of dark factories, there will still be a demand for skilled workers. Investing in education and training programs can prepare the workforce for the evolving manufacturing landscape.

Emphasis on Sustainability

Adopting sustainable practices is crucial for long-term success. Developing countries can learn from dark factories' focus on minimizing waste and energy optimization, ensuring that their manufacturing sectors are environmentally conscious.

Collaboration and Partnerships

Working together with governments, private sectors, and educational institutions can drive innovation and support the implementation of dark factory models. For example, partnerships between tech firms and universities can foster technological advancements that benefit the manufacturing sector.

Adaptability to Market Changes

The ability to adapt to shifting market conditions is paramount. Dark factories showcase how manufacturers can efficiently scale operations and modify production lines to meet consumer needs.

By embracing these lessons, developing nations can position themselves as competitive players in the global manufacturing arena, leveraging the advantages offered by dark factories.

Embracing the Future of Manufacturing

The rise of dark factories signifies a major shift in the manufacturing industry, fueled by technological advancements and the continuous push for greater efficiency. As manufacturers consider the potential returns, it is clear that the benefits of transition toward automation can outweigh the initial costs. Industry leaders are coming to recognize the growing importance of dark factories in shaping manufacturing's future. Simultaneously, developing nations can harness valuable lessons from this pioneering model.

As we approach 2030, the use of dark factories is set to grow, fundamentally changing how goods are produced and setting higher standards for efficiency and quality. Embracing these innovations is vital for manufacturers aiming to thrive in our increasingly competitive global marketplace.

Comments