Block Making Machines

Our block making machines are of the highest quality and are designed to make your block making process efficient and cost-effective. We offer the best equipment on the market, so you can be sure that you’re investing in a product that will last. Our machines come at the best price with worldwide delivery. Choose us for your block making needs and you won't be disappointed.

QT4-26 Block Making Machine

QT4-26 block making machine is one of our small block making machine, it is semi automatic, suitable for making all types of hollow blocks, solid block, pavers, curbstones and so on. Now in order to suit the overseas markets and ensure the machine work more efficiently, we have used many parts of some well-known brands imported from overseas countries.

QT4-25 Block Making Machine

QT4-25 block making machine is a kind of automatic product developed by our company newly, adopts flat vibration, mould vibration, and squeeze compression vibration, manufactures the blocks with average density and high strength. And the unique dose charging device and the strong material-distributing structure ensure the block's quality of various materials .It adopts PLC control ,and realizes the automatic plate-supplying, material-distributing ,and brick-discharging .With the high efficiency ,it is the ideal equipment to manufacture the new stylewall material.

QT4-16 Block Making Machine

QT4-16 block making machine one kind of concrete block making machine in our company . It is mainly used in building , bridges , roads . Can make solid block , hollow block by changing the molds . Very popular in the country which need for construction .The machine's price was also very suitable in this area.

QT5-15 Automatic Concrete Cement Block Making Machine

QT5-15 automatic concrete cement block making machine is our core competence block machine, it is full automatic can make all types of hollow blocks, solid blocks, pavers, curbstones and so on. it adopts our most advanced hydraulic system and vibration system, can ensure the block quality very good and the working noise very low. We cooperated with SIEMENS, SCHNEIDER, OMRON, CALYCA and so on to make sure our block machine with high quality and keep our machine work more stable.

QT6-15 Block Making Machine Full Automatic

QT6-15 block making machinery full automatic is one machine with multifunction. Changing molds can produce various kinds of specification porous bricks, standard bricks, hollow bricks, with a double material-feeding machine can produce all kinds of thecolored road bricks, grassland bricks, and slope protection bricks etc.

QT8-15 Block Making Machine

QT8-15 Block making machine is one of our hot sales machine models, it is full automatic work with PLC,can all kinds of hollow blocks, solid block, pavers, curbstones and so on. Adopts our latest hydraulic pressure,can ensure the block quality very good. Now in order to suit the overseas markets and ensure the machine work more efficiently, we have used many parts of some well-known brands imported from overseas countries.

QT10-15 Block Making Machine

QT10-15 block making machine is our hot sales automatic block machine, adopting advanced hydraulic pressure technology and vibration technology, can ensure the block quality is very strong. We cooperated with SIEMENS, SCHNEIDER, OMRON , YUKAN and so on to make sure our block machine with high quality and keep our machine work more stable.

QT12-15 Automatic Block Machine

QT12-15 Automatic Block Machine is one of our hot sales block making machine which can make all kinds of block by changing the mold,such as hollow block,solid block,paver,curbstone and so on.Adopting advanced technology and good material,can ensure the machine running with stable and low-level working noise,bricks produced with high strength.

QT15-15 Automatic Block Making Machine

QT15-15 automatic block making machine adopts articular storage and description material system to insure the feeding accuracy and avoiding the effect of exterior material. So the products have high density. Adopting synchronization vibration insures the products making average. Combine with long-distance controlling system, it can achieve scrutiny, controlling, diagnosis It doesn’t need a professional person but only need a simple training to the operator. It produces various bricks/blocks etc.

GMT Block Pallet

GMT Block Pallet

Advantage:

1. Light weight:The density of our GMT pallet for concrete block is 1.2g/cm3 better than PVC brick pallet(1.75g/cm3-1.8g/cm3) So the weight of our GMT pallet lighter than PVC pallet.

2. Endurable: Our GMT pallet for concrete block can be used for 8-10 years.

3. Impact resisitance: You can hit our GMT pallet for concrete block whatever you want.

4. High loading capacity: It’s lower flexure of our GMT pallet for concrete block.

5. Abrasion resistant: the abrasion resistance is better than pvc pallet and wood pallet.

6. Customize size.

Material Feeding System

Part one: Wheel Loader

Feature:

To guarantee the quality we use the top brand wheel loader in the world, we has 1.5 ton and 2 ton wheel loader, using a wheel loader can save 3-4 workers, also it can make the producing time shorter, and make the whole production line produce more fluent.

-

1.5ton wheel loader usually suit for our QT5, QT6 and QT7 block machine

-

2 ton wheel loader usually suit for our QT8, QT10, QT12 and QT15 block machine

Part two: Batching machine

Feature:

Our batching machine is cumulative weighing, to make the material came out the more accurate, and our batching machine has PLD800 and PLD1200 to fit for different machine.

-

PLD800 usually suit for our QT4 block machine

-

The two aggregate hoppers with capacity of 4m3 for each are used for storage of sand and stone. It consists of the stationery frame which is used for supporting hoppers and fixing the weighing system and belt conveyors.

-

PLD1200 usually suit for our QT5, QT6, QT7, QT8, QT10, QT12 and QT15 blocks machine

-

The three aggregate hoppers with capacity of 4m3 for every hopper are used for storage of sand and stone. It consists of the stationery frame which is used for supporting hoppers and fixing the weighing system and belt conveyors.

Part three: Mixer

Feature:

The mixer use to mix the raw material to concrete, it can mix the material Stir well and the production capacity is bigger. Can ensure the machine production line automatically. All of our mixer add the Lining steel inside and the lining steel use manganese steel, can ensure the mixer with longer service life. After many years, the customer only need change the lining steel is ok. The unitized time of the powder metering system is convenient for maintenance and accurate measurement.

Cement Delivery System

Part one: Cement Silo

Feature:

1. Convenient installation;

2. Rain-proof and moisture-proof;

3. Several volume capacity suitable for different demand;

4. Green filter reduce dust leakage;

5. Equipped with butterfly valve,safety valve,leave swith and arch-broken;

Part two: Cement Scale

Feature:

It can weigh the cement, it can keep accurate concrete mixture ratio.

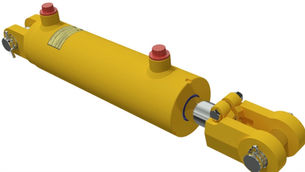

Block Transfer System

Part one: Automatic pallet feeding machine

Function:

The machine feeds pallet into pallet hopper automatically, it needs only one forklift driver to carry pallets onto the conveyor of the pallet feeding machine. It adopts hydraulic pressure power to ensure working process more stably.

The features and advantages of automatic pallet feeding machine:

1. Adopt PLC intelligent control system (PLC frequency converter, hydraulic pressure), save labor & labor cost, and increase production efficiency!

2. Chain-style conveyor system

3. With protection system, high-position anti-roof system

4. 30cm of the maximum calibration distance of pallet (calibration distance)

5. The upper pallet feeding system adopts inverter control system: soft contact, fast compression, no damage to the pallet

6. Lifting capacity of pallet feeding system (Lifting capacity is not affected by weight): the lifting action of the hydraulic control system (counterbalance valve) keeps the same height every time, and also keeps the high accuracy.

7. Pallet is automatically lowered into the regular position after it’s conveyed, next, pallet feeding system will automatically execute feeding action!

8. No-pallet detector: get to work upon detecting a pallet there, a sensor senses before the chain is transmitted, and get non-work upon detecting no-pallet there.

Part two: Stacker

Function:

This device transfers the pallets with wet blocks and stack them layer by layer automatically, two pallets once.

Features:

There are two kinds of stacker machine:

-

Single Pallet fixed type: The stacker is fixed in one position, and only one pallet can be stacked at a time. It is often used for small brick making machines.

-

Mobile type: stacking two pallets at a time, moving the stacking as a whole, commonly used to maintain medium and large brick machines

Advantages:

-

Labor-saving: Stacking machine can save 1-2 labors.It can reduce production costs for customers and save about 10,000 USD in capital each year

-

Fast cycle speed; No matter how many layers of bricks and pallets, they can be raised and moved at a evenly speed.

-

High degree of automation, no need to use people to lift the pallets from stacking to stacking, It can work with forklifts, and continuous production can be performed 24 hours.

-

Time saving: When bricks and pallets are stacked in multiple layerss, the forklift driver can work once every 3 minutes, which improves work efficiency

-

The stacker also can reduces the damage of finished wet blocks and improves the yield.

Part three: Forklift

Function:

-

We use the forklift to carry block from block machine area to curing area

-

It could help you for transport block to truck when you sale the block

Advantages:

-

Reliable special meters:

(1) Integrated meter and steering column offers reasonable structure and better view.

(2) The meter integrates water temperature gauge, oil level gauge, hour meter and other alarms to make monitoring of truck condition easier

(3) When the engine has fault, the indicator will be on all the time.

-

New adjusting mechanism of steering wheel:

Dual-screw-type adjusting mechanism of steering wheel improves operation comfort and reliability

-

Wide view mast:

(1) The superior mast ensures operation safety. Wide view mast improve the front view.

(2) Enlarged channel surface make structure firmer.

(3) The wide view mast is the standard configuration of the truck. It has better view.

-

Environment-friendly design and easy maintenance:

(1) Engine meeting China emission standard stage lll Is assembled on the truck

(2) Built-in noise isolating and sealing materials reduce vibration and noise.

(3) Opening angle of engine hood makes maintenance easier.

(4) The engine hood is easy to open and reliable to lock.

(5) The gas spring with automatic lock function ensures the safety during maintenance.

(6) The truck has lower vibration and noise.

-

Air Inlet System:

The air suction is installed on top of the overhead guard column where is away from the dust produced when travelling, The air sucked by the engine is cleaner and thus the engine service life is prolonged.

-

Reliable casting steering axle:

(1) Compact structure,small deformation when loading.

(2) Dust proof and water proof structure increasing service life and reliability effectively.

(3) Low maintenance cost in later stage.

Automatic Block Cuber System

Multi-function Type Automatic Block Cuber System

Function:

This automatic palletizing system can separate bricks and pallets of different specifications produced by different models of brick machines, layout the bricks, and finally arrange them into 1000 or 1200 (mm) cuber stacks for stacking,

the standard solid bricks (height : 115mm) can be stacked at one time up to 12 layers.

The stretch film packaging can be selected after the brick is discharged. It can be directly carried to the site for stacking without a pallet when matched with a forklift drag clamp, and use forklift can stacking blocks 3 stacks.

Advantages:

1. The whole system is controlled by PLC + touch screen, only one person is required to operate it.

2. This system can save 7-9 workers , help block factory save about USD10,0000 cost per year.

3. With high capacity , can separate about 3800 pallet per day, much fast than block machine production speed.

4. Just adjust the parameters to replace the stacked bricks, from hollow bricks to pavement bricks.

Get a Quote

Get in touch with us today to get a quote and learn more about our offerings.

Book an Appointment

When it comes to block making machines, you deserve nothing short of excellence, and that's precisely what Amindus Consulting and Solutions offers. With a wealth of experience and a proven track record, our team of dedicated professionals provides customized, cutting-edge solutions tailored to your specific needs. From initial consultation to post-purchase support, we are committed to delivering exceptional service and ensuring your operations run smoothly and efficiently. By choosing Amindus Consulting and Solutions, you are not just investing in high-quality machinery, but also in a partnership that prioritizes your success. Book an appointment with us today and take the first step towards transforming your block making processes into a seamless, highly productive endeavor.