Aluminium & PVC Machinery

We provide high quality PVC and Aluminium machinery to meet all your production line needs. Our products are reliable and durable, and are designed to last. We offer delivery worldwide, so no matter where you are located, you will receive your products quickly and efficiently. Our team of experienced professionals can help you find the right solution for your industrial needs. We look forward to helping you get the most out of your production line.

ACK 420 – UP-CUTTING SAW MACHINE

ACK 420 is designed for the strait or angular cutting operations of the large size of profiles made of PVC and aluminium materials by means of Ø 420 mm of saw blade.

ACK 550 – UP-CUTTING SAW MACHINE

ACK 550 is designed for the strait or angular cutting operations of the large size of profiles made of PVC and aluminum materials by means of Ø 550 mm of saw blade.

ACK 550 – UP-CUTTING SAW MACHINE

ACK 550 is designed for the strait or angular cutting operations of the large size of profiles made of PVC and aluminum materials by means of Ø 550 mm of saw blade.

CK 412 – PVC GLAZING BEAD SAW

CK 412 is an automatically operating cutting machine designed for 45 ° cutting of PVC glazing bead profiles

VK 420 – V CUTTING & 90° END NOTCHING MACHINE

VK 420 is designed for the precise V cutting, arrow cutting and 90° end notching operations with minimal off cut size on PVC and aluminum profiles

RYK 420 – RADIAL SAW MACHINE

RYK 420 Radial Saw Machine is designed for the strait or angular cutting operations of the large size of materials made of PVC, aluminium, brass, teflon, bakelite, wood and other non-ferrous metals . RYK 420 allows straight and angular cuttings by means of the pivoting and tilting head

MK 420 – MK 420PS – MK 450 – MANUAL UP-CUTTING SAW MACHINE

MK 420, MK 420 PS and MK 450 , manual up-cutting saw machines is designed for the straight and angular cutting operations of PVC aluminium, brass, wood and non-ferrous materials with the cost at very nominal rates . The machine can be used for two purposes; the lateral cutting mode and longitudinal cutting mode.

DC 421 MS – DOUBLE HEAD MITRE SAW MACHINE

DC 421 MS is designed for the strait or angular cutting operations of large size of profiles made of PVC and aluminium materials by means of double head sawing units equipped with Ø 420 mm of saw blades

DC 421 PBS – DOUBLE HEAD MITRE SAW MACHINE (FULL AUTOMATIC)

DC 421 PBS is a fully automatic sawing machine that is designed for the strait or angular cutting operations of large size of profiles made of PVC and aluminium materials by means of double head sawing units equipped with Ø 420 mm of saw blades

DC 421 PS – DOUBLE HEAD MITRE SAW MACHINE (FULL AUTOMATIC)

DC 421 PS is a fully automatic sawing machine that is designed for the strait or angular cutting operations of large size of profiles made of PVC and aluminium materials by means of double head sawing units equipped with Ø 420 mm of saw blades

DC 550 PB – DOUBLE HEAD MITRE SAW MACHINES

DC 550 PB is full automatic sawing machines that is designed for the strait or angular cutting operations of large size of profiles made of PVC and aluminium materials by means of double head sawing units equipped with Ø 550 mm of saw blades.

DC 550 SKH – DOUBLE HEAD MITRE SAW MACHINE (FULL AUTOMATIC)

DC 550 SKH is full automatic sawing machines that is designed for the straight or angular cutting operations of large size of profiles made of PVC and aluminum materials by means of double head sawing units equipped with Ø 550 mm of saw blades.

DC 550 SK – FULL AUTOMATIC DOUBLE HEAD MITRE SAW MACHINES

DC 550 SK is full automatic sawing machines that is designed for the straight or angular cutting operations of large size of profiles made of PVC and aluminum materials by means of double head sawing units equipped with Ø 550 mm of saw blades.

KD 350 P – MITER SAW MACHINE

KD 350P Miter saw cutting machines are designed for straight and angular cutting of PVC, aluminum and wooden profiles

KD 350 D – MITER SAW MACHINE

KD 350D Miter saw cutting machines are designed for straight and angular cutting of PVC, aluminum and wooden profiles

KD 350 M – MITER SAW MACHINE

KD 350 M Miter saw cutting machines are designed for straight and angular cutting of PVC, aluminum and wooden profiles

KD 400 M – MITRE SAW MACHINE

KD 400 M Mitre saw cutting machine is designed for straight and angular cutting of PVC, aluminum and wooden profiles

KD 400 D – MITER SAW MACHINE

KD 400D Miter saw cutting machines are designed for straight and angular cutting of PVC, aluminum and wooden profiles

KD 400 P – MITER SAW MACHINE

KD 400P Miter saw cutting machines are designed for straight and angular cutting of PVC, aluminum and wooden profiles

TK 500 – SINGLE CORNER PVC WELDING MACHINE

This machine is ideal for the single corner welding of PVC profiles at 90°. Adjustment of standard (2 mm) or seamless (0.2 mm) welding options manually

DK 502 – DOUBLE CORNER PVC WELDING MACHINE

Machine is ideal for welding process of PVC plastic profiles at two corners.

TK 505 – SINGLE CORNER PVC WELDING MACHINE

This machine is ideal for the single corner welding of PVC profiles between 30°- 180° .Adjustment of standard (2 mm) or seamless (0.2 mm) welding options manually

DK 540 – FOUR CORNER PVC WELDING MACHINE

Machine is ideal for welding process of PVC plastic profiles at four corners

CA 601 – SEMI-AUTOMATIC PVC SINGLE CORNER CLEANING MACHINE

CA 601 Single Corner Cleaning Machine used to clean lower and upper surfaces and outer corners of PVC profiles welded at 90° angle.

CA 603 – PVC CORNER CLEANING MACHINE (4 – 6 CUTTERS)

CA 603 Single Corner Cleaning Machine is used for striping of bottom and top surfaces and cleaning outer corners of 90° PVC cleaning profiles.

SM 206 – FULLY AUTOMATIC DOUBLE HEAD REINFORCEMENT STEEL SCREWDRIVER

This machine is used to screw reinforcement steel sheet to PVC door and window profiles precisely and fast.

SM 1000 – AUTOMATIC DOUBLE HEAD REINFORCEMENT STEEL SCREWING MACHINE

Automatic screwing of the steel reinforcement bars in the PVC profiles.

SM 201 – SINGLE HEAD REINFORCEMENT STELL SCREWDRIVER

Used for screwing of reinforcement steel on the PVC door and window profiles fast and precisely

CNC 608 – PVC CORNER CLEANING MACHINE (2 AXIS)

Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90° CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives

CNC 610 -PVC CORNER CLEANING MACHINE (4 AXIS)

Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90° CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives

PIM 6509 – PVC PROFILE PROCESSING CENTER

PIM 6509 is 8-axis CNC controlled machining center which is specifically designed to process any kind of PVC profiles in the market. The machine can do all operations on four sides of PVC profiles such as milling, opening key holes, water slots, hinge holes, handle holes, marking, saw blade cutting etc. PIM 6509 has the programming feature which provides minimum waste and maximum amount of production. 7 pieces of PVC profiles can be placed on the feeding conveyor of the machine and 3-axis pneumatic gripper moves them into the milling & cutting center for the milling and cutting operations. Operator attaches barcodes on the processed profiles to make them ready for welding operation.

PIM 6508 -PVC PROFILE PROCESSING CENTER

PIM 6508 is 8-axis CNC controlled machining center which is specifically designed to process any kind of PVC profiles in the market. The machine can do all operations on four sides of PVC profiles such as milling, opening key holes, water slots, hinge holes, handle holes, marking, saw blade cutting etc. PIM 6508 has the programming feature which provides minimum waste and maximum amount of production. 10 pieces of PVC profiles can be placed on the feeding conveyor of the machine and 3-axis pneumatic gripper moves them into the milling & cutting center for the milling and cutting operations. Operator attaches barcodes on the processed profiles to make them ready for welding operation.

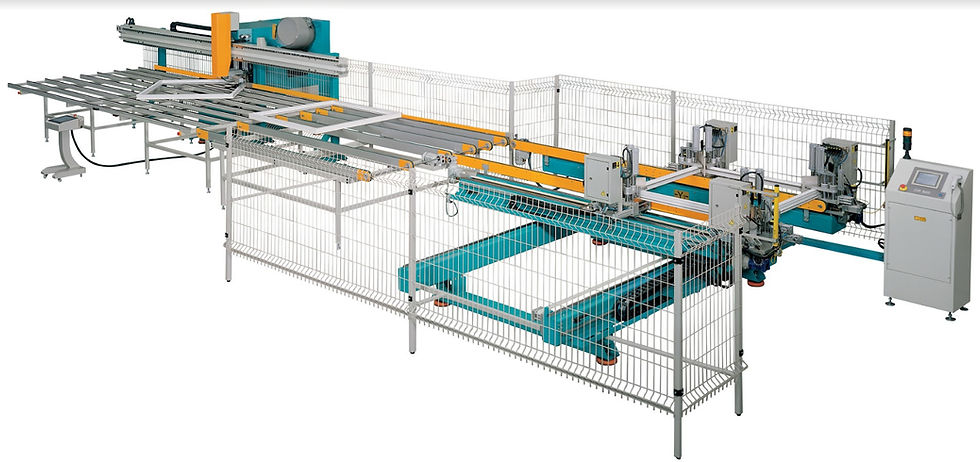

PCC 6505 – AUTOMATIC PROFILE CUTTING CENTER

PCC 6505 is a servo-controlled machine which is specifically designed for the serial cutting of any kind of PVC and aluminum profiles in the market. The machine is able to cut PVC and aluminum profiles into required dimension. Operator places 10 pieces of profiles of maximum length of 6.5 m and minimum length of 0.7 m on the feeding conveyor of the machine, and presses on start button.Machine start the cutting operation of the profiles with the help of high performance robot arm and saw unit as per the requested angle between the angle of 45⁰-135° then collocates them on the outlet conveyor. Operator attaches barcodes on the machined profiles to make them ready for the assembly.

CCL 1660 -PVC CORNER CLEANING MACHINE

CNC controlled four corner PVC welding and cleaning line that provides movement in 2 and 4 axes. After welding process at DK 540, the frame goes to the Cooling Unit (SA 250) automatically. Then the Robot Unit (SA 260) automatically takes the frames from the Cooling Unit (SA 250) where the cleaning process starts and carries it by turning to the CNC 608 or 610 Cleaning Machine

MEM 128 -SEMI-AUTOMATIC MULTIPLE END MILLING MACHINE

Machine which works with motor–belt mechanism, ideal for the serial end milling operations on PVC and aluminum profiles precisely

CRM 201 S – TEMPLATE COPY ROUTER MACHINE WITH TRIPLE HOLE & WATER SLOT DRILLING

It is used for the processing of slots for locks, drilling handles, triple, hinges, espagnolette holes and opening water drain slot on PVC and aluminium profiles CRM 201S Template copy router with triple holes and water slot drilling features

CRM 250 S – TEMPLATE COPY ROUTER MACHINE

It is designed to operate quickly and precisely lock’s holes on aluminum and PVC profiles, without releasing the workpiece in one cycle . It is also used for the drilling handles, hinges, espagnolette holes and opening water drain slot on PVC and aluminum profiles.

FR 221 S -PNEUMATIC TEMPLATE COPY ROUTER

It is used for the processing of slots for locks, drilling handles, hinges, espagnolette holes and opening water drain slot on PVC and aluminium profiles up to 3 mm of thickness.

FR 225 S – TEMPLATE COPY ROUTER WITH TRIPLE HOLE DRILL

It is used for the processing of slots for locks, drilling handles, hinges, espagnolette and barrel holes and opening water drain slot on PVC and aluminum profiles up to 3 mm of thickness.

KM 211 – MANUAL END MILLING MACHINE

Machine which works manually, ideal for end milling operations on PVC and aluminium profiles precisely.

FR 226 S – AUTOMATIC COPY ROUTER MACHINE

It is used for the processing of slots for locks, drilling handles, hinges, espagnolette an barrel holes and opening water drain slot on PVC and aluminium profiles up to 3 mm of thickness.

KM 215 – SEMI-AUTOMATIC END MILLING MACHINE

Machine which works with hydro-pneumatic system, ideal for the end milling operations on PVC and aluminum profiles precisely.

IRON CUTTING MACHINE

→ IRON CUTTING MACHINE

→ 7.5KW, 10HP

TK 503 – SINGLE CORNER PVC WELDING MACHINE

This machine is ideal for the single corner welding of PVC profiles between 30°- 180°.

400 SIZE REFRIGERATED ALUMINUM AND PVC CUTTING MACHINE

→ 400 SIZE REFRIGERATED ALUMINUM AND PVC CUTTING MACHINE

→ RIGHT LEFT METERS AVAILABLE

→ MAINTAINED AND READY FOR SHIPPING

AIR DRYERS

AIR DRYERS

PENMAK SINGLE HEAD WELDING

PENMAK SINGLE HEAD WELDING MACHINE MAINTENANCE OK, VERY GOOD CONDITION

AIR DRYER FILTERS

AIR DRYER FILTERS

1000 LITER VERTICAL AIR TANK

1000 LITER VERTICAL AIR TANK

FILTER INSIDE ELEMENTS

FILTER INSIDE ELEMENTS

SVK 270 BELT-PULLEY DRIVE SCREW COMPRESSOR

SVK 270 BELT-PULLEY DRIVE SCREW COMPRESSOR

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 100 VSD BELT-PULLEY SCREW COMPRESSOR - WITH INVERTER

SVK 100 VSD BELT-PULLEY SCREW COMPRESSOR - WITH INVERTER

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

The Variable Speed Drive (Inverter) System provides energy savings of up to 35% by enabling the compressor to operate according to the momentary air requirement of the enterprise.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 150 BELT-PULLEY DRIVE SCREW COMPRESSOR

SVK 150 BELT-PULLEY DRIVE SCREW COMPRESSOR

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 100 DC VSD DIRECT COUPLED SCREW COMPRESSOR - INVERTER

SVK 100 DC VSD DIRECT COUPLED SCREW COMPRESSOR - INVERTER

The high efficiency electric motor coupled to the screw group removes the losses by directly moving the screw group. This type of 1: 1 drive system is called Direct Coupled. Direct Coupled Models work 30% more efficiently than belt and pulley models. As the coupling element is easy to change, it serves the user for many years with less maintenance cost.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

The Variable Speed Drive (Inverter) System provides energy savings of up to 35% by enabling the compressor to operate according to the momentary air requirement of the enterprise. Soft landing and take-off and low screw speed increase the energy saving of the compressor.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 75 VSD BELT-PULLEY DRIVEN SCREW COMPRESSOR - INVERTER

SVK 75 VSD BELT-PULLEY DRIVEN SCREW COMPRESSOR - INVERTER

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

The Variable Speed Drive (Inverter) System provides energy savings of up to 35% by enabling the compressor to operate according to the momentary air requirement of the enterprise.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 100 DC DIRECT COUPLED SCREW COMPRESSOR

SVK 100 DC DIRECT COUPLED SCREW COMPRESSOR

The high efficiency electric motor coupled to the screw group removes the losses by directly moving the screw group. This type of 1: 1 drive system is called Direct Coupled. Direct Coupled Models work 30% more efficiently than belt and pulley models. As the coupling element is easy to change, it serves the user for many years with less maintenance cost.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 75 DC DIRECT COUPLED SCREW COMPRESSOR

SVK 75 DC DIRECT COUPLED SCREW COMPRESSOR

SVK 75 BELT-PULLEY DRIVE SCREW COMPRESSOR

SVK 75 BELT-PULLEY DRIVE SCREW COMPRESSOR

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 75 DC VSD DIRECT COUPLED SCREW COMPRESSOR - INVERTER

SVK 75 DC VSD DIRECT COUPLED SCREW COMPRESSOR - INVERTER

The high efficiency electric motor directly connected to the screw group by coupling removes the losses by moving the screw group directly. This type of 1: 1 drive system is called Direct Coupled. Direct Coupled Models work 30% more efficiently than belt and pulley models. It serves the user for many years with less maintenance cost.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

The Variable Speed Drive (Inverter) System provides energy savings of up to 35% by enabling the compressor to operate according to the momentary air requirement of the enterprise.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 50 BELT-PULLEY DRIVEN SCREW COMPRESSOR WITH INVERTER

SVK 50 BELT-PULLEY DRIVEN SCREW COMPRESSOR WITH INVERTER

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

The Variable Speed Drive (Inverter) System provides energy savings of up to 35% by enabling the compressor to operate according to the momentary air requirement of the enterprise.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 30 BELT-PULLEY DRIVE SCREW COMPRESSOR

SVK 30 BELT-PULLEY DRIVE SCREW COMPRESSOR

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 50 BELT-PULLEY DRIVE SCREW COMPRESSOR

SVK 50 BELT-PULLEY DRIVE SCREW COMPRESSOR

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 20-TK TANK MOUNTED SCREW COMPRESSOR

SVK 20-TK TANK MOUNTED SCREW COMPRESSOR

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency IE2 type electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Tank top models are a good solution for businesses that have space problems. They do not take up much space. It is integrated on the dryer tank.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation. Sound level has been measured to be 68 dB in our tank top models.

Vibration is reduced to zero with vibration wedges. In terms of sound and vibration levels, it is suitable for positioning in closed areas.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Our on-tank Screw Compressors are divided into models with and without Air Dryer.

The Refrigerated Type Air Dryer is mounted on the tank in a way that it dries the air flow rate suitable for the requested pressure.

Refrigerated Type Air Dryers may differ in air drying production according to the climate of the geography, atmosphere temperature and relative humidity.

All data should be taken into account when making a choice.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 20 BELT-PULLEY DRIVE SCREW COMPRESSOR

SVK 20 BELT-PULLEY DRIVE SCREW COMPRESSOR

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 20-T TANK MOUNTED SCREW COMPRESSOR

SVK 20-T TANK MOUNTED SCREW COMPRESSOR

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency IE2 type electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Tank top models are a good solution for businesses that have space problems. They do not take up much space. It is integrated on the dryer tank.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation. Sound level has been measured to be 68 dB in our tank top models.

Vibration is reduced to zero with vibration wedges. In terms of sound and vibration levels, it is suitable for positioning in closed areas.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Our on-tank Screw Compressors are divided into models with and without Air Dryer.

The Refrigerated Type Air Dryer is mounted on the tank in a way that it dries the air flow rate suitable for the requested pressure.

Refrigerated Type Air Dryers may differ in air drying production according to the climate of the geography, atmosphere temperature and relative humidity.

All data should be taken into account when making a choice.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 15-TK TANK MOUNTED SCREW COMPRESSOR-AIR DRYER

SVK 15-TK TANK MOUNTED SCREW COMPRESSOR-AIR DRYER

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency IE2 type electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Tank top models are a good solution for businesses that have space problems. They do not take up much space. It is integrated on the dryer tank.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation. Sound level has been measured to be 68 dB in our tank top models.

Vibration is reduced to zero with vibration wedges. In terms of sound and vibration levels, it is suitable for positioning in closed areas.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Our on-tank Screw Compressors are divided into models with and without Air Dryer.

The Refrigerated Type Air Dryer is mounted on the tank in a way that it dries the air flow rate suitable for the requested pressure.

Refrigerated Type Air Dryers may differ in air drying production according to the climate of the geography, atmosphere temperature and relative humidity.

All data should be taken into account when making a choice.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 15-T TANK MOUNTED SCREW COMPRESSOR

SVK 15-T TANK MOUNTED SCREW COMPRESSOR

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency IE2 type electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Tank top models are a good solution for businesses that have space problems. They do not take up much space. It is integrated on the dryer tank.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation. Sound level has been measured to be 68 dB in our tank top models.

Vibration is reduced to zero with vibration wedges. In terms of sound and vibration levels, it is suitable for positioning in closed areas.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Our on-tank Screw Compressors are divided into models with and without Air Dryer.

The Refrigerated Type Air Dryer is mounted on the tank in a way that it dries the air flow rate suitable for the requested pressure.

Refrigerated Type Air Dryers may differ in air drying production according to the climate of the geography, atmosphere temperature and relative humidity.

All data should be taken into account when making a choice.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 15 BELT-PULLEY DRIVE SCREW COMPRESSOR

SVK 15 BELT-PULLEY DRIVE SCREW COMPRESSOR

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 10-TK TANK MOUNTED SCREW COMPRESSOR-AIR DRYER

SVK 10-TK TANK MOUNTED SCREW COMPRESSOR-AIR DRYER

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency IE2 type electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Tank top models are a good solution for businesses that have space problems. They do not take up much space. It is integrated on the dryer tank.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation. Sound level has been measured to be 65 dB in our tank top models.

Vibration is reduced to zero with vibration wedges. In terms of sound and vibration levels, it is suitable for positioning in closed areas.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Our on-tank Screw Compressors are divided into models with and without Air Dryer.

The Refrigerated Type Air Dryer is mounted on the tank in a way that it dries the air flow rate suitable for the requested pressure.

Refrigerated Type Air Dryers may differ in air drying production according to the climate of the geography, atmosphere temperature and relative humidity.

All data should be taken into account when making a choice.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 10 BELT-PULLEY DRIVE SCREW COMPRESSOR

SVK 10 BELT-PULLEY DRIVE SCREW COMPRESSOR

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation.

Vibration is reduced to zero with vibration wedges.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

SVK 10-T TANK MOUNTED SCREW COMPRESSOR

SVK 10-T TANK MOUNTED SCREW COMPRESSOR

The V type toothed belt and pulley system connected to the screw group is driven by a high efficiency IE2 type electric motor.

It provides a high level of performance with the combination of screw group, suction group, oil tank and separator mount that prevents oil leaks.

Tank top models are a good solution for businesses that have space problems. They do not take up much space. It is integrated on the dryer tank.

Excellent cooling is provided by the large bladed propeller type cooler positioned behind the engine.

In addition, screw, motor and fan sounds are minimized with compressor internal insulation. Sound level has been measured to be 65 dB in our tank top models.

Vibration is reduced to zero with vibration wedges. In terms of sound and vibration levels, it is suitable for positioning in closed areas.

All the equipment used in the compressor was included in the product after the necessary tests were carried out as a result of the cooperation of the leading brands of the industry with Setkom.

With the easy-to-use Digital PLC Control Panel, you can easily observe the warning, operating hour, internal and operating pressure information for 6 different situations.

Our on-tank Screw Compressors are divided into models with and without Air Dryer.

The Refrigerated Type Air Dryer is mounted on the tank in a way that it dries the air flow rate suitable for the requested pressure.

Refrigerated Type Air Dryers may differ in air drying production according to the climate of the geography, atmosphere temperature and relative humidity.

All data should be taken into account when making a choice.

Free air efficiency was measured according to ISO 1217 Annex C Standard at 1 atmosphere air pressure, 0% relative humidity and 20oC air inlet temperature.

Tolerance at flow rates ± 6%

WS - 131S WING COLLECTING STATION

WS/131 S | WING COLLECTING STATION

Used to assembly all Tilt&Turn hardware systems on different types, various, sizes of

window &door sash profiles without tape measure and pencil using, without need

for molds and templates, provides speedy, high quality and standard assembling.

OPTIONS

ASD- Full Automatic Screwing with two steps, Automatic screew feeding unit,

Laser pointer

TD- Movable adjustable triple handle hole drilling group with air cooling (with

reinforced profile) 10*12*10

HD- Semi automatic adjustable, Hinge drilling and manual hinge screwing group

(Multifunctional revolver system)(2 step system for 3-6 mm)

BC- Milling tool for espagnolette channel grooving and air unit (12-16 mm)

EO-FR-S- Hardware shelf (Lighting and Functional corner element hanger)

WS - 131 WING COLLECTING TABLE

WS/131 | WING COLLECTING TABLE

Used to assembly all Tilt&Turn hardware systems on different types, various, sizes of

window &door sash profiles without tape measure and pencil using, without need

for molds and templates, provides speedy, high quality and standard assembling.

OPTIONS

ASD- Full Automatic Screwing, Automatic screew feeding unit, Laser pointer

TD- Triple handle hole drilling group (with reinforced profile) 10*12*10

HD- Semi automatic adjustable, Hinge drilling and manual hinge screwing group

(Multifunctional revolver system)(2 step system for 3-6 mm)

BC- Milling tool for espagnolette channel grooving (12-16 mm)

EO-FR-S- Hardware shelf (Lighting and Functional corner element hanger)

FS - 775 THREE HEADS CASE COLLECTION TABLE

FS/775 | THREE HEADS CASE COLLECTION TABLE

Triple head frame assembly table. (Servo controlled)

Automatic centering of window’s frame (Automatic positioning)

Automatic measurement system (Servo controlled)

Compatible with all amount & kind of hinges

3D hinges servo controlled drilling unit

Horizontal drilling for hinge of door sash profile

FS - 701 CASE COLLECTION TABLE

FS/701 | CASE COLLECTION TABLE

Allows to drill holes in one time by multi drilling system and automatic screwing

of tilt&turn hardware hinges used on different series and sizes of window & door

frame profiles, without tape measure, pencil and template using.

Frame fixing with automatic centering

According the furniture type horizontal and vertical action usable multi drilling unit

Possibility to drill all hinge holes and screw places with single move by one button

OPTIONS

ASD- Full automatic vertical screwdriver.Automatic screw feeding unit. Laser

pointer

FS - 771 DOUBLE HEAD CASE COLLECTION TABLE

FS/771 | DOUBLE HEAD CASE COLLECTION TABLE

Double head frame assembly table. (Servo controlled)

Automatic centering of window’s frame (Automatic positioning)

Automatic measurement system (Servo controlled)

Compatible with all amount & kind of hinges

3D hinges servo controlled drilling unit

FS - 751 DOUBLE FRAME HINGE PLACE DRILLING MACHINE

FS/751 | DOUBLE FRAME HINGE PLACE DRILLING MACHINE

Allows to drill holes in one time by multi drilling system of tilt&turn hardware hinges

used on different series and sizes of window & door frame profiles, without tape

measure, pencil and template using.

Frame fixing with automatic centering

According the furniture type vertical action usable double head multi drilling unit

Possibility to drill all hinge holes in profile with reinforcement steel and screw

places with single move by one button

Suitable for all types of frame profiles

SD - 205 FULLY AUTOMATIC SINGLE HEAD SCREWING MACHINE

SD/205 | FULLY AUTOMATIC SINGLE HEAD SCREWING MACHINE

Automatic determination screw position with sensor

Automatic recharge the screwdriver

Discharge of product after finish

Possibility of screwing for 8 different profile width

Full automatic PLC controlled screw fidding unit

Automatic stop after screwing

Protective sensor to prevent faulty use

Height adjustment sensor for special screws

Profile backing support

Manual screw feeding from screen

Average screwing speed: 1,7 sec./pcs

Long term using for screwing head by protector

WS - 130 WING COLLECTING TABLE

WS/130 | WING COLLECTING TABLE

Used to assembly Tilt&Turn hardware systems on different types, various, sizes of

window & door sash profiles. Provides speedy, high quality and standard assembling

OPTIONS

HD- Semi automatic adjustable, Hinge drilling and manual hinge screwing group

(Multifunctional revolver system)(2 step system for 3-6 mm)

EO-FR-S- Hardware shelf (Lighting and Functional corner element hanger)

SD - 206 FULLY AUTOMATIC DOUBLE HEAD SCREWING MACHINE

SD/206 | FULLY AUTOMATIC DOUBLE HEAD SCREWING MACHINE

Automatic determination screw position with sensor

Two screws at the same time

Automatic recharge the screwdriver

Discharge of product after finish

Possibility of screwing for 8 different profile width

Full automatic PLC controlled screw fidding unit

Automatic stop after screwing

Protective sensor to prevent faulty use

Height adjustment sensor for special screws

Profile backing support

Manual screw feeding from screen

Average screwing speed: 1,7 sec./pcs

Long term using for screwing head by protector

SD - 201 AUTOMATIC VERTICAL SCREWING MACHINE

SD/201 | AUTOMATIC VERTICAL SCREWING MACHINE

Pneumatic unit of automatic screw feeding

Pedal control of automatic screwing

Automatic stop after screwing

Height adjustment sensor for special screws

Automatic clamping of profile during screwing

Adjustable range stops supporting profile

SD - 205MD FULLY AUTOMATIC SINGLE HEAD SCREWING MACHINE ASSEMBLY DRILLED

SD/205 MD | FULLY AUTOMATIC SINGLE HEAD SCREWING MACHINE ASSEMBLY DRILLED

Automatic determination screw position with sensor

Automatic recharge the screwdriver

Discharge of product after finish

Possibility of screwing for 8 different profile width

Full automatic PLC controlled screw fidding unit

Automatic stop after screwing

Protective sensor to prevent faulty use

Height adjustment sensor for special screws

Profile backing support

Manual screw feeding from screen

Average screwing speed: 1,7 sec./pcs

Long term using for screwing head by protector

Easy adjustment possibility for 8 different sizes of profiles by revolver system after

selected on touch screen for screwing.

Montage drilling possibility with profile size ( manual from screen or from barcode

SD - 204 DOUBLE AUTOMATIC VERTICAL SCREWING MACHINE MOVING

SD/204 | DOUBLE AUTOMATIC VERTICAL SCREWING MACHINE MOVING

Pneumatic unit of automatic screw feeding

Pedal control of automatic screwing

Automatic stop after screwing

Foot pedal control for flawless screwing

Height adjustment sensor for special screws

Automatic clamping of profile during screwing

Adjustable range stops supporting profile

Durable use of bit and easy change possibility

Average screwing speed: 1,7 sec./pcs

SD - 101 MANUAL SCREWING AND AUTOMATIC FEEDING UNIT

SD/101 | MANUAL SCREWING AND AUTOMATIC FEEDING UNIT

Used in windows and doors manufacturing for reinforced steel, espagnolette and

hinge screwing.

Pneumatic unit of automatic screw feeding

Speedy and fasty usage

With easy movable feature work in different places

Prevents the waste of fallen screws

SD - 201S AUTOMATIC VERTICAL SCREWING MACHINE

Full automatic PLC controlled screw fidding unit

Pedal control of automatic screwing

Automatic recharge the screwdriver

Sensor for screw recognition

Laser pointer

Automatic stop after screwing

Foot pedal control for flawless screwing

Protective sensor to prevent faulty use

Height adjustment sensor for special screws

Automatic clamping of profile during screwing

Adjustable range stops supporting profile

Durable use of bit and easy change possibility

Average screwing speed: 1,7 sec./pcs

WS - 134SW WING COLLECTING STATION WITH WATER DRAIN

WS/134 SW | WING COLLECTING STATION WITH WATER DRAIN

Used to assembly all Tilt&Turn hardware systems on different types, various, sizes of

window &door sash profiles without tape measure and pencil using, without need

for molds and templates, provides speedy, high quality and standard assembling.

Suitable for all kind of Tilt & Turn and accessories assembling

OPTIONS

ASD- Full Automatic Screwing with two steps, Automatic screew feeding unit,

Laser pointer

TD- Movable adjustable triple handle hole drilling group with air cooling (with

reinforced profile) 10*12*10

HD- Semi automatic adjustable, Hinge drilling and manual hinge screwing group

(Multifunctional revolver system)(2 step system for 3-6 mm)

BC- Milling tool for espagnolette channel grooving and air unit (12-16 mm)

EO-FR-S- Triple hardware shelf (Lighting and Functional corner element hanger)

SW - Full automatic water slot drilling system with 4 motors (Inside and outside

water slot channel opening)

FW - 441 FOUR CORNER WELDING MACHINE

FW/441 | FOUR CORNER WELDING MACHINE

Used to weld four corners of PVC profiles at 90° at the same time

12” touch screen panel

CNC control system (3 axes)

Resistance teflon wrapping system

Possibility for 0.2 mm welding for all profile types

Automatic mould opening system makes the welding seams thinner at separating

point. Also easy change mould system.

Possibility to follow the process of heating the resistance (programming for different

profiles)

Tender measurement system

240 - 250 frames / 8 hours

OPTIONS

Barcode system

Gasket clamp system

Welding moulds

Can be performed according the working position (reverse or direct line)

Preheating system for cold profile in winter time

DW - 241 DOUBLE HEAD WELDING MACHINE

DW/241 | DOUBLE HEAD WELDING MACHINE

Synchronous double corner welding of PVC profiles between 50°-180°

White and color profiles welding with 0.2 mm seam restriction.

Special rolled system of teflon

All movable parts of machine goes on rail system

At the expense of strong system make a perfect weld

Stock for welding mould

Easy mould change system

Digital control system for weld and press time

Long lasting heating plates

The mobile head is stoped by special hidropneumatic system

PLC control system and programming possibility for different profiles

OPTIONS

Welding Mould

Preheating system for cold profile in winter time.

Gasket pressing system

DS - 501 AUTOMATIC DOUBLE HEAD CUTTING MACHINE

DS/501 | AUTOMATIC DOUBLE HEAD CUTTING MACHINE

Double head cutting mitre saw for PVC and Aluminyum profiles

Easy and accurate positioning system by servo motor

Automatic tilt movement of the saw heads to 45° and 90°

Angles between 45° and 90° can be adjusted manually.

The 500 mm saw blade diametre enables to cut 2 profiles at the same time.

For both PVC and Aluminyum cutting is used two 2.2 kW motors.

12,1’ PLC control system with touchscreen

All movable parts of machine goes on rail system

Automatic closing safety system

Automatic slicing

Cutting possibility for long profile

OPTIONS

Barcode printer

Cooling and hydro-pneumatic system to cut aluminum profiles

Absorbent unit for collecting the sawdust

DG - 604 CNC DOOR PROCESSING CENTER

DG/604 | CNC DOOR PROCESSING CENTER

Used for drilling operations in a door sash of different types and series of PVC profiles

with reinforcement steel inside. Used for: all types of mechanisms of vertical locks; locks

for the toilet/bath (WC); locks with cylinder mechanism; locks for room doors; handle

assembling holes; cylinder mechanism and channel lock slot

Multilock handle and sistematic programming

Special door lock espagnolette holes finish in one operation

Channel grooving for profile with square reinforced steel

Sefaty guard sensor

Movable conveyor warning lights

CS - 803 FULLY AUTOMATIC MIDDLE REGISTRATION WEDGE BINDING MACHINE DIGITAL CONTROL

CS/803 | FULLY AUTOMATIC MIDDLE REGISTRATION WEDGE BINDING MACHINE DIGITAL CONTROL

Automatic screwing of mullion connectors used on different series and sizes of PVC

mullion profiles, in one time from both sides, positioning without settings.

Easy adjustment possibility for 8 different sizes of profiles by revolver system after

selected on touch screen for screwing.

Automatic screwing with double side automatic screw feeding unit

Automatic positioning for different mullion connectors by revolver system

Automatic clamp and profile centering system

Connector joining speed 6 sec./pcs

CS - 801 AUTOMATIC MIDDLE REGISTRATION WEDGE MOUNTING SYSTEM

CS/801 | AUTOMATIC MIDDLE REGISTRATION WEDGE MOUNTING SYSTEM

Automatic screwing of mullion connectors used on different series and sizes of PVC

mullion profiles, in one time from both sides, positioning without settings.

Possibility to use 6 types of mullion connector in the same time without change settings

Automatic screwing with double side automatic screw feeding unit

Automatic clamp and profile centering system

Possibility for easy setting and position change

Connector joining speed 6 sec./pcs

CG - 301 GLASS MOUNTING UNIT

CG/301 | GLASS MOUNTING UNIT

Fast installation of glass on the windows and doors

Glazed joinery transferring to package on rollers

Parallel block clamps allow you to set an appropriate balance

Raising the workspace up for easier installation

CC - 222 CNC CORNER CLEANING MACHINE

CC/222 | CNC CORNER CLEANING MACHINE

Used to clean the welded corners by 90° of PVC profiles

Movable 8,4” touch screen panel

CNC control system (2 axes)

Up & bottom gasket hole drills (2 tool)

Up & bottom inner corner cleaning system (special patented design) (2 tool)

Up & bottom color-colorless surface cleaning blade system (4 tool)

Frame outside corner cleaning saw ø250 (1 tool)

Cleaning performace processed by only 9 tool.

Easy system for profile setup and programming

Adjustment of operating speeds to the desired speed

Automatic lubrication of oil with over alert system

Shift processing capacity: 190-200 items / 8 hours

Unlimited possibility of reserve program files on flash card and send the data to other machine.

BS - 401 DIGITAL LATCH CUTTING CENTER

BS/401 | DIGITAL LATCH CUTTING CENTER

Automatic cutting of glazing bead PVC profiles

Cutting speed arrangement system

Pneumatic clamping system with vertical adjustment of mold

Exact measurement of welded construction with a digital measuring system

Easy data transfer from the measuring device to the machine via Bluetooth

Positioning of conveyor by servomotor on transferred sizes or inputed sizes from screen

Ability to cut two glazing beads at same time.

OPTIONS

Digital ruler measuring system

ZB 2010 - FULL AUTOMATIC DOUBLE HEAD CUTTING MACHINE

It cuts PVC and aluminum profiles precisely between 45-90 degrees.

Thanks to its 2.2 Kw powerful motor, it provides comfortable aluminum cutting.

The saw diameter is 500 mm and it has diamond teeth. 155 mm from the saw cutting surface. comes forward.

It provides the opportunity to cut two 60's or 70's profiles at the same time.

Double head min. 430 mm. max. 3750 mm. cuts.

Thanks to the drive system with dimensions of more than 3750 mm, the machine profile itself can be driven 7000 mm. it can cut to size.

It has a cooling system in order to cut aluminum profiles without burrs.

It has automatic slicing feature. You can automatically slice the length profile in the size and quantity you want.

The moving head moves on the linear rail.

It provides easy use thanks to its PLC and touch panel controlled screen.

It automatically cuts the measurements and numbers entered into its memory, respectively. You can save a maximum of 6000 measurements in its memory.

Each time the machine is turned on, it automatically makes the calibration setting.

ZB 2020 - FULL AUTOMATIC DOUBLE CORNER WELDING MACHINE

0.2 mm. Thanks to its welding feature, you can produce joinery with aesthetic appearance in the weld track.

It has a Teflon coil resistance system.

Easily adjustable welding mold is given by machine.

It has PLC system. (Fully automatic program control system)

After placing the profile on the machine, you only have to press the start button, the other works are done by the machine itself.

Single corner welding is possible on the moving head for angles other than 45º.

ZB 1010 - BOTTOM CUTTING MACHINE

It cuts PVC and aluminum profiles precisely between 45-90 degrees.

Saw diameter is 450 mm and has diamond teeth.

Turntable; It provides the opportunity of cutting without loss (45º). After cutting one corner of the profile, you can easily rotate the table and cut the other corner without removing the profile.

Right and left meters are given by machine.

ZB 1020 - AUTOMATIC SINGLE CORNER WELDING MACHINE

Welding at an angle between 30-180 degrees

0.2 mm. Thanks to its welding feature, you can produce joinery with aesthetic appearance in the weld track.

Fully automatic program control system

Digital adjustment of heating, melting and cooling times and degrees

Possibility to save source settings for 5 different profiles

Easily adjustable adjustable welding mold is given by machine.

ZB 1040 - MEDIUM RECORDING MACHINE

Brand: Makpen Makina

Year of Manufacture: 2018

ZB 1030 - AUTOMATIC LATCH CUTTING MACHINE

Adjustable lath mold according to each profile is given by machine.

There are 4 saws in total, 2 on each engine, and thanks to these saws, the nails of the lath are cut.

Nail removal size can be adjusted according to the desired level.

ZB 1050 - TRIPLE HANDLE DRILLING, COPY MILLING AND WATER DRAINING MACHINE

It is a milling machine designed to open espagnolette, barrel lock, window arm holes and water discharge holes of PVC and aluminum profiles.

Thanks to HERTZ brand brushless spingle (high speed) milling motor, even if you run your machine for 24 hours without stopping, there will be no heating in the engine and it provides a smooth operation.

It has a wide template with adjustable espagnolettes, barrel lock and drain hole molds in all sizes.

An optional cooling system is offered for a burr-free, problem-free milling of aluminum profiles.

ZB 1070 - ALUMINUM CORNER JOINING PRESS

It is a machine designed to press aluminum profiles to each other precisely at 90º.

Pressing side blades move at the same time as they move from a single piston.

The machine works with a hydro-pneumatic system.

Profile support arms are movable and can be adjusted up and down.

Front triangle support can be adjusted up and down.

Side blades can be adjusted easily as they move on the gear shaft.

ZB 1060 - AUTOMATIC CORNER CLEANING MACHINE

It is a machine designed to clean the lower, upper and outer surfaces of the welding burrs formed in the corners of the welded PVC profiles.

Fully automatic program control system

It has a profile recognition system, you do not need to choose a blade. The machine recognizes the profile to be cornered with its sensors and automatically performs the cleaning process by bringing the required blade.

There is a support that enables adjustment for 4 blades separately.

ZB 1080 - AUTOMATIC TRIPLE WATER DRAINING MACHINE

It has a pneumatic press system.

The forward-backward and height adjustments of the milling heads can be made easily thanks to adjustable bolts with snaps.

Milling movement speeds can be adjusted as desired.

There are different buttons for each milling motor.

The time adjustment of the machine movements can be accelerated or slowed down as desired.

Get a Quote

Get in touch with us today to get a quote and learn more about our offerings.

The Ultimate Guide to Selecting the Ideal Machinery and Production Line for Aluminium and PVC Windows and Doors: A Comprehensive Analysis

Sustainable Solutions for Modern Manufacturing

Exploring the Impact of Innovative Partnerships in Advanced Manufacturing Technologies

Book an Appointment

Are you looking for high-quality Aluminium and PVC machinery? Look no further than Amindus Consulting and Solutions. Our team of experts can help you find the perfect machinery to meet your needs. Book an appointment with us today and let us help you take your business to next level.