A Complete Guide to Industrial Belt Types: V-Belts, Flat Belts, Timing Belts, and Their Uses

- Amindus Consulting and Solutions

- Dec 3, 2025

- 4 min read

Presented by Amindus Consulting and Solutions

Industrial pulley systems rely heavily on the right belt to transfer power efficiently and reliably. Choosing the correct belt type can improve machine performance, reduce downtime, and extend equipment life. This guide explores the most common belt types used in industrial applications: V-belts, flat belts, and timing belts. It covers their key uses, strengths, weaknesses, and offers practical advice on selecting and maintaining the right belt for your needs.

V-Belts: Versatile and Widely Used

V-belts are one of the most common belt types in industrial pulley systems. Their trapezoidal cross-section fits into matching grooves on pulleys, creating friction that transmits power efficiently.

Key Applications

Industrial machinery such as compressors, pumps, and conveyors

Automotive engines for driving alternators, water pumps, and air conditioning compressors

Agricultural equipment like tractors and harvesters

Advantages

High power transmission capability due to wedging action in pulley grooves

Compact design allows for smaller pulley sizes and tighter layouts

Good slip resistance under varying loads

Easy to install and replace

Disadvantages

Wear and stretch over time require regular tension adjustment

Limited speed range compared to some other belt types

Heat buildup can reduce belt life in high-speed or heavy-load applications

Practical Example

A factory conveyor system uses V-belts to drive rollers. The belts provide reliable power transfer and can handle sudden load changes without slipping. Regular inspection for cracks and proper tensioning keeps the system running smoothly.

Flat Belts: Simple and Efficient for Light Loads

Flat belts are made from flexible materials like leather, rubber, or synthetic fabrics. They run on flat pulleys and are often used where smooth, quiet operation is needed.

Key Applications

Textile machinery where gentle handling is important

Light-duty conveyors and assembly lines

Office equipment such as printers and copiers

Advantages

Low cost and easy to manufacture

Smooth, quiet operation with minimal vibration

Can cover long distances between pulleys

Simple to adjust and maintain

Disadvantages

Lower power transmission compared to V-belts or timing belts

Prone to slipping under heavy loads or sudden acceleration

Requires larger pulley diameters to avoid bending stress

Practical Example

A printing press uses flat belts to drive rollers that feed paper. The belts provide smooth motion without damaging delicate materials. Regular cleaning and alignment prevent belt wear and slippage.

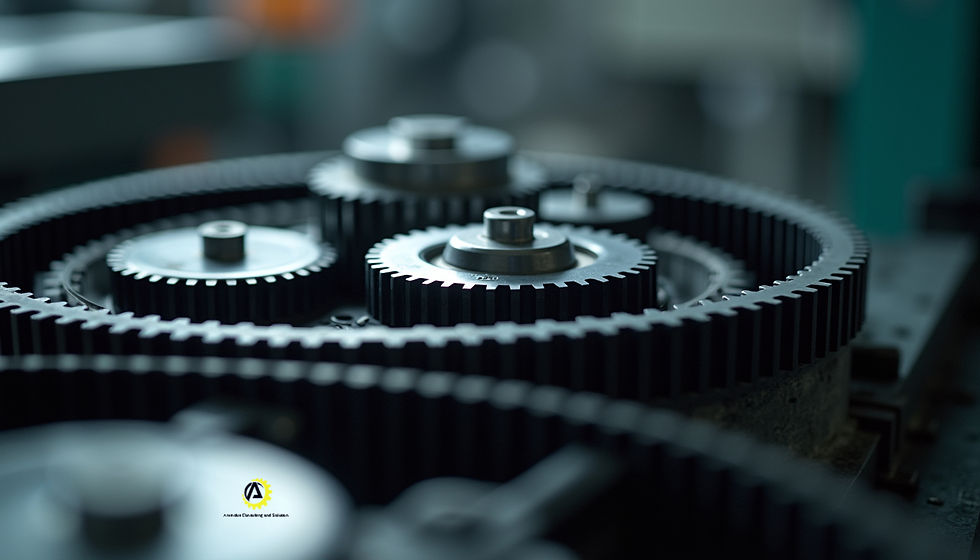

Timing Belts: Precision and Synchronization

Timing belts have teeth that mesh with matching grooves on pulleys, ensuring no slip and precise timing. They are essential where synchronization between shafts is critical.

Key Applications

Automotive engines for camshaft timing

Robotics and automation where exact positioning is required

3D printers and CNC machines for accurate movement control

Advantages

No slip ensures precise timing and positioning

High efficiency with minimal power loss

Low maintenance due to reduced wear

Can handle high speeds and loads

Disadvantages

More expensive than V-belts or flat belts

Requires precise alignment and tensioning

Limited flexibility in pulley size and layout

Practical Example

A CNC milling machine uses timing belts to control the X and Y axes. The belts ensure the cutting tool moves exactly as programmed, producing high-precision parts. Regular tension checks and avoiding contamination extend belt life.

How to Choose the Right Belt for Your Application

Selecting the correct belt depends on several factors. Consider these points to make an informed choice:

Power and torque requirements: Higher loads often need V-belts or timing belts.

Speed and precision: Timing belts excel where exact synchronization is critical.

Environmental conditions: Heat, moisture, and chemicals affect belt material choice.

Space constraints: V-belts allow compact designs; flat belts need more room.

Maintenance capabilities: Some belts require frequent tensioning or replacement.

Cost considerations: Flat belts are generally cheaper but less durable.

Selection Tips

For heavy-duty industrial drives, V-belts offer a balance of power and cost.

For precision machinery, timing belts provide accuracy and reliability.

For light loads and long-distance power transfer, flat belts are suitable.

Always check manufacturer specifications for belt size, material, and compatibility.

Consider belt tensioners and guards to improve safety and performance.

Maintenance Tips to Extend Belt Life

Proper maintenance can significantly increase the lifespan of any belt type. Follow these guidelines:

Regular inspection for cracks, fraying, or glazing

Maintain correct tension to prevent slipping or excessive wear

Keep pulleys clean and aligned to avoid uneven belt wear

Avoid exposure to oils, solvents, and extreme temperatures

Replace belts at the first sign of damage to prevent equipment failure

Use belt dressing sparingly and only when recommended by the manufacturer

Practical Maintenance Example

In a manufacturing plant, scheduled belt inspections every month catch early signs of wear on V-belts. Adjusting tension and replacing worn belts before failure reduces downtime and repair costs.

Choosing the right belt type for your pulley system is crucial for efficient and reliable operation. V-belts offer versatility and power for many industrial uses. Flat belts provide smooth, quiet motion for lighter loads. Timing belts deliver precision and synchronization where accuracy matters most. Understanding the strengths and weaknesses of each type helps you select the best option for your specific needs.

Regular maintenance, including inspection, tensioning, and cleaning, ensures belts last longer and machines run smoothly. By applying these insights, you can improve equipment performance, reduce downtime, and save costs over time.

Comments